Types of control valve

There are essentially three types of control valve; poppet valves, spool valves and rotary valves.Poppet valves

In a poppet valve, simple discs, cones or balls are used in conjunction with simple valve seats to control flow. Figure 4.9 shows the construction and symbol of a simple 2/2 normally-closed valve, where depression of the pushbutton lifts the ball off its seat and

allows

fluid to flow from port P to port A. When the button is released,

spring and fluid pressure force the ball up again closing the valve.

allows

fluid to flow from port P to port A. When the button is released,

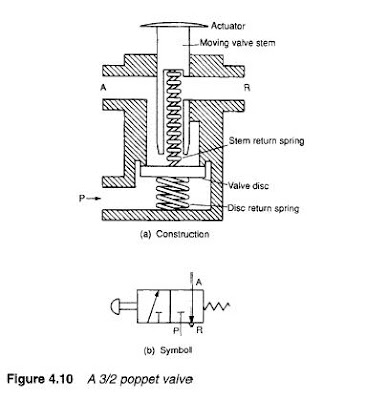

spring and fluid pressure force the ball up again closing the valve.Figure 4.10 shows the construction and symbol of a disc seal 3/2 poppet. With the pushbutton released, ports A and R are linked via the hollow pushbutton stem. If the pushbutton is pressed, port R is first sealed, then the valve disc pushed down to open the valve and connect ports P and A. As before, spring and fluid pressure from

port P closes the valve.

The valve construction and symbol shown in Figure 4.11 is a poppet changeover 4/2 valve using two stems and disc valves. With the pushbutton released, ports A and R are linked via the hollow left-hand stem and ports P and B linked via the normally-open right hand disc valve. When the pushbutton is pressed, the link between ports A and R is first closed, then the link between P and B closed.

The link between A and P is next opened, and finally the link between B and R opened. When the pushbutton is released, air and spring pressure puts the valve back to its original state.

Poppet valves are simple, cheap and robust, but it is generally simpler to manufacture valves more complicated than those shown in Figure 4.11 by using spool valves. Further, a major disadvantage of poppet valves is the force needed to operate them. In the poppet valve of Figure 4.10, for example, the force required on the pushbutton

to operate the valve is P x a newtons. Large capacity valves need large valve areas, leading to large operating force. The high pressure in hydraulic systems thus tends to prevent use of simple

poppet valves and they are, therefore, mainly found in low pressure pneumatic systems.

Spool valves

poppet valves and they are, therefore, mainly found in low pressure pneumatic systems.

Spool valvesSpool (or slide) valves are constructed with a spool moving horizontally within the valve body, as shown for the 4/2 valve in Figure 4.12. Raised areas called 'lands' block or open ports to give the required operation.

The operation of a spool valve is generally balanced. In the valve construction in Figure 4.12b, for example, pressure is applied to opposing faces D and E and low tank pressure to faces F and G.

There is no net force on the spool from system pressure, allowing the spool to be easily moved.

Figure

4.13 is a changeover 4/2 spool valve. Comparison of the valves shown

in Figures 4.12 and 4.13 shows they have the same body construction, the

only difference being the size and position of lands on the spool. This

is a major cost-saving advantage of spool valves; different operations

can be achieved with a common body and different spools. This obviously

reduces manufacturing costs.

Figure

4.13 is a changeover 4/2 spool valve. Comparison of the valves shown

in Figures 4.12 and 4.13 shows they have the same body construction, the

only difference being the size and position of lands on the spool. This

is a major cost-saving advantage of spool valves; different operations

can be achieved with a common body and different spools. This obviously

reduces manufacturing costs.Figure 4.14 shows various forms of three position changeover valves; note, again, these use one body with different functions achieved by different land patterns.

Spool valves are operated by shifting the spool. This can be achieved by button, lever or striker, or remotely with a solenoid.

Self-centring can easily be provided if springs are mounted at the end of the spool shaft.

Solenoid-operated valves commonly work at 24 V DC or 110 V AC. Each has its own advantages and disadvantages. A DC power supply has to be provided for 24 V DC solenoids, which, in large systems, is substantial and costly. Operating current of a 24 V solenoid is higher than a 110 V solenoid's. Care must be taken with plant cabling to avoid voltage drops on return legs if a common single line return is used.

Current through a DC solenoid is set by the winding resistance. Current in an AC solenoid, on the other hand, is set by the inductance of the windings, and this is usually designed to give a high inrush current followed by low holding current. This is achieved by using the core of the solenoid (linked to the spool) to raise the coil inductance when the spool has moved. One side effect of this is that a jammed spool results in a permanent high current which can damage the coil or the device driving it.

Each and every AC solenoid should be protected by an individual fuse. DC solenoids do not suffer from this characteristic. A burned out DC solenoid coil is

almost unknown.

Whatever form of solenoid is used it is very useful when fault finding to have local electrical indication built into the solenoid plug top. This allows a fault to be quickly identified as either an electrical or hydraulic problem. Fault finding is discussed further in Chapter 8.

A solenoid can exert a pull or push of about 5 to 10 kg. This is adequate for most pneumatic spool valves, but is too low for direct operation of large capacity hydraulic valves. Here pilot operation must be used, a topic discussed later.

Rotary valves

Rotary valves consist of a rotating spool which aligns with holes in the valve casing to give the required operation. Figure 4.15 shows the construction and symbol of a typical valve with centre off action.

Rotary valves are compact, simple and have low operating forces. They are, however, low pressure devices and are consequently mainly used for hand operation in pneumatic systems.

Pilot-operated valves

With large capacity pneumatic valves (particularly poppet valves) and most hydraulic valves, the operating force required to move the valve can be large. If the required force is too large for a solenoid or manual operation, a two-stage process called pilot operation is used.

The principle is shown in Figure 4.16. Valve 1 is the main operating valve used to move a ram. The operating force required to move the valve, however, is too large for direct operation by a solenoid, so a second smaller valve 2, known as the pilot valve, has been added to allow the main valve to be operated

by

system pressure. Pilot pressure lines are normally shown dotted in

circuit diagrams, and pilot ports on main valves are denoted Z, Y, X and

so on.

by

system pressure. Pilot pressure lines are normally shown dotted in

circuit diagrams, and pilot ports on main valves are denoted Z, Y, X and

so on.In Figure 4 16, pilot port Z is depressurised with the solenoid deenergised, and the ram is retracted. When the solenoid is energised valve 2 changes over, pressurising Z; causing valve 1 to energize and the ram to extend.

Although pilot operation can be achieved with separate valves it is more usual to use a pilot/main valve assembly manufactured as a complete ready made unit. Figure 4.17 shows the operation of a pilot-operated 3/2 pneumatic valve. The solenoid operates

the small pilot valve directly. Because this valve has a small area, a low operating force is required. The pilot valve applies line pressure to the top of the control valve causing it to move down, closing the exhaust port. When it contacts the main valve disc there are two forces acting on the valve stem. The pilot valve applies a downwards force of P x D, where P is the line pressure and D is the area of the control valve. Line pressure also applies an upwards force P x E to the stem, where E is the area of the main valve.

The area of the control valve, D, is greater than area of the main valve E, so the downwards force is the larger and the valve opens.

When the solenoid de-energises, the space above the control valve is vented. Line an spring pressure on the main valve causes the valve stem to rise again, venting port A.

A hydraulic 4/2 pilot-operated spool valve is shown in Figure4.18. The ends of the pilot spool in most hydraulic pilot-operated valves are visible from outside the valve. This is useful from a maintenance viewpoint as it allows the operation of a valve to be

checked. In extreme cases the valve can be checked by pushing the pilot spool directly with a suitably sized rod (welding rod is ideal !).

Care must be taken to check solenoid states on dual solenoid valves before attempting manual operation. Overriding an energised AC solenoid creates a large current which may damage the coil, (or blow the fuse if the solenoid has correctly installed protection).

Check valves

Check valves only allow flow in one direction and, as such, are similar in operation to electronic diodes. The simplest constructionis the ball and seat arrangement of the valve in Figure 4.19a, commonly used in pneumatic systems. The right angle construction in Figure 4.19b is better suited to the higher pressures of a hydraulic

Check valves only allow flow in one direction and, as such, are similar in operation to electronic diodes. The simplest constructionis the ball and seat arrangement of the valve in Figure 4.19a, commonly used in pneumatic systems. The right angle construction in Figure 4.19b is better suited to the higher pressures of a hydraulic

system. Free flow direction is normally marked with an arrow on the valve casing.

system. Free flow direction is normally marked with an arrow on the valve casing.A check valve is represented by the graphic symbols in Figure 4.20. The symbol in Figure 4.20a is rather complex and the simpler symbol in Figure 4.20b is more commonly used.

Figure

4.21 illustrates several common applications of check valves. Figure

4.21a shows a combination pump, used where an application requires large

volume and low pressure, or low volume and high pressure. A typical

case is a clamp required to engage quickly (high volume and low

pressure) then grip (minimal volume but high pressure). Pump 1 is the

high volume and low pressure pump, and pump 2 the high pressure pump. In

high volume mode both pumps deliver to the system, pump 1 delivering

through the check valve V 3. When high pressure is required, line

pressure at X rises operating unloading valve V 1 via pilot port Z

taking pump 1 off load. Pump 2 delivers the required pressure set by

relief valve V 2, with the check valve preventing fluid leaking back to

pump 1 and V1.

Figure

4.21 illustrates several common applications of check valves. Figure

4.21a shows a combination pump, used where an application requires large

volume and low pressure, or low volume and high pressure. A typical

case is a clamp required to engage quickly (high volume and low

pressure) then grip (minimal volume but high pressure). Pump 1 is the

high volume and low pressure pump, and pump 2 the high pressure pump. In

high volume mode both pumps deliver to the system, pump 1 delivering

through the check valve V 3. When high pressure is required, line

pressure at X rises operating unloading valve V 1 via pilot port Z

taking pump 1 off load. Pump 2 delivers the required pressure set by

relief valve V 2, with the check valve preventing fluid leaking back to

pump 1 and V1.Figure 4.21b shows a hydraulic circuit with a pressure storage device called an accumulator (described in a later chapter). Here a check valve allows the pump to unload via the pressure regulating valve, while still maintaining system pressure from the accumulator.

A spring-operated check valve requires a small pressure to open (called the cracking pressure) and acts to some extent like a low pressure relief valve. This characteristic can be used to advantage.

In Figure 4.21c pilot pressure is derived before a check valve, and in Figure 4.21 d a check valve is used to protect a blocked filter by diverting flow around the filter when pressure rises. A check valve is also included in the tank return to prevent fluid being sucked out of the tank when the pump is turned off.

Pilot-operated check valves

The cylinder in the system in Figure 4.22 should, theoretically, hold position when the control valve is in its centre, off, position. In practice, the cylinder will tend to creep because of leakage in the control valve.

Check valves have excellent sealage in the closed position, but a simple check valve cannot be used in the system in Figure 4.22 because flow is required in both directions. A pilot-operated check is similar to a basic check valve but can be held open permanently by application of an external pilot pressure signal.

There are two basic forms of pilot-operated check valves, shown in Figure 4.23. They operate in a similar manner to basic check valves, but with pilot pressure directly opening the valves. In the 4C valve shown in Figure 4.23a, inlet pressure assists the pilot. The

symbol

of a pilot-operated check valve is shown in Figure 4.23c. The cylinder

application of Figure 4.22 is redrawn with pilot operated check valves

in Figure 4.23d. The pilot lines are connected to the pressure line

feeding the other side of the cylinder. For any cylinder movement, one

check valve is held open by flow (operating

symbol

of a pilot-operated check valve is shown in Figure 4.23c. The cylinder

application of Figure 4.22 is redrawn with pilot operated check valves

in Figure 4.23d. The pilot lines are connected to the pressure line

feeding the other side of the cylinder. For any cylinder movement, one

check valve is held open by flow (operatingas a normal check valve) and the other is held open by pilot pressure. For no required movement, both check valves are closed and the cylinder is locked in position.

Restriction check valves

The speed of a hydraulic or pneumatic actuator can be controlled by adjusting the rate at which a fluid is admitted to, or allowed out from, a device. This topic is discussed in more detail in Chapter 5 but a speed control is often required to be direction-sensitive and this requires the inclusion of a check valve.

A restriction check valve (often called a throttle relief valve in pneumatics) allows full flow in one direction and a reduced flow in the other direction. Figure 4.24a shows a simple hydraulic valve and Figure 4.24b a pneumatic valve. In both, a needle valve sets restricted flow to the required valve. The symbol of a restriction

check valve is shown in Figure 4.24c.

Figure 4.24d shows a typical application in which the cylinder extends at full speed until a limit switch makes, then extend further at low speed. Retraction is at full speed.

A restriction check valve V 2 is fitted in one leg of the cylinder. With the cylinder retracted, limit-operated valve V 3 is open allowing free flow of fluid from the cylinder as it extends. When the striker plate on the cylinder ram hits the limit, valve V 3 closes and flow out of the cylinder is now restricted by the needle valve setting

of valve V 2. In the reverse direction, the check valve on valve V 2 opens giving full speed of retraction.

0 comments:

Post a Comment